Coated Roofing Machine: A Comprehensive Guide to the Benefits and Uses

Introduction:

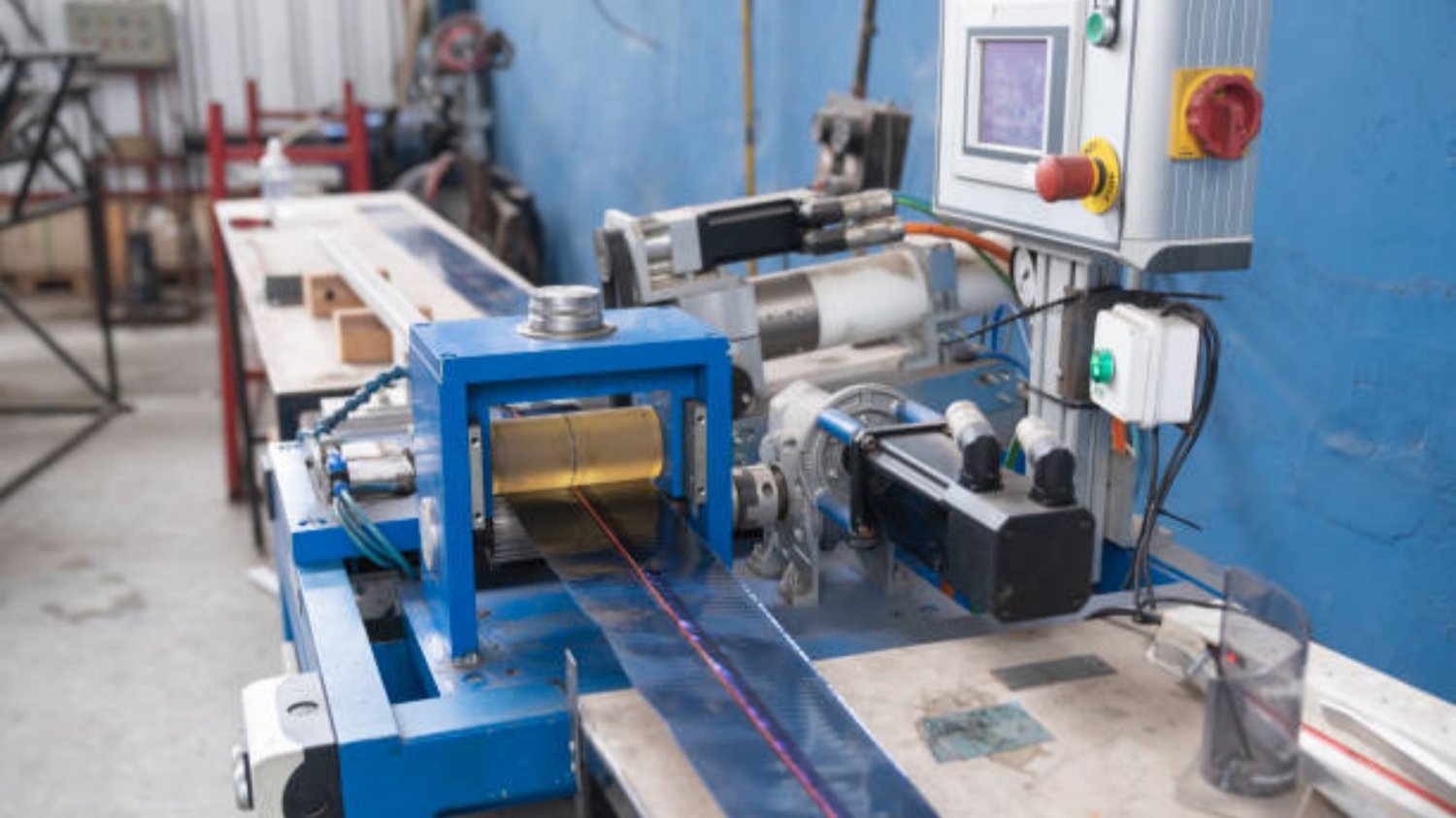

A coated roofing machine plays a crucial role in the manufacturing and installation of coated roofing materials. This innovative piece of equipment automates the process of applying protective coatings to roofing materials, enhancing their durability and performance. In this article, we will explore the various aspects of coated roofing machines, including their benefits, uses, and the importance they hold in the construction industry.

1. Understanding Coated Roofing Machines

Coated roofing machines are specialized machines designed to apply protective coatings to roofing materials such as metal sheets, shingles, tiles, and more. These machines utilize advanced technology to ensure precise and consistent application of coatings, resulting in a uniform finish and enhanced durability of the roofing material.

2. Benefits of Coated Roofing Machines

Coated roofing machines offer numerous benefits that make them indispensable in the roofing industry. Firstly, these machines save time and labor by automating the coating process, allowing for faster production and installation of coated roofing materials. Additionally, the uniform application of coatings ensures enhanced protection against weather elements, prolonging the lifespan of the roofing material.

3. Enhanced Durability and Performance

One of the primary advantages of using a coated roofing machine is the improved durability and performance of the roofing material. The protective coatings applied by these machines act as a barrier against UV radiation, moisture, and other harmful elements. This helps prevent corrosion, rusting, and other forms of damage, ultimately extending the lifespan of the roof.

4. Versatility and Customization of Coated Roofing Machines

Coated roofing machines offer versatility in terms of the types of coatings that can be applied to roofing materials. Whether it's a reflective coating for energy efficiency or a fire-resistant coating for added safety, these machines can accommodate various coating options, allowing for customization based on specific project requirements.

5. Cost-effectiveness of Coated Roofing Machines

Investing in a coated roofing machine can result in long-term cost savings. By automating the coating process, these machines reduce the need for manual labor, saving on labor costs. Moreover, the enhanced durability of coated roofing materials reduces the frequency of repairs and replacements, further reducing maintenance expenses over time.

6. Environmental Friendliness of Coated Roofing Machines

Coated roofing machines contribute to environmental sustainability by promoting energy efficiency. Many coating options available for these machines are designed to reflect sunlight, reducing the amount of heat absorbed by the roof. This, in turn, reduces the energy required for cooling, leading to lower carbon emissions and energy consumption.

7. Applications of Coated Roofing Machines

Coated roofing machines find applications in various sectors of the construction industry. These machines are commonly used in the manufacturing of metal roofing sheets, where they apply protective coatings to enhance their resistance to corrosion and weathering. Additionally, coated roofing machines are utilized in the installation of shingles, tiles, and other roofing materials to ensure their longevity and performance.

8. Maintenance and Care

To ensure optimal performance and longevity of a coated roofing machine, regular maintenance and care are essential. This includes routine cleaning, inspection of components, lubrication of moving parts, and timely replacement of worn-out or damaged parts. Adhering to the manufacturer's maintenance guidelines will help maximize the lifespan and efficiency of the machine.

9. Choosing the Right Coated Roofing Machine

When selecting a coated roofing machine, it is crucial to consider factors such as the type of roofing materials you work with, the desired coating options, and the production volume. Consulting with industry experts and conducting thorough research will help you choose a machine that best meets your specific requirements and budget.

10. Conclusion

Coated roofing machines have revolutionized the roofing industry by streamlining the process of applying protective coatings to roofing materials. These machines offer numerous benefits, including enhanced durability, customization options, cost-effectiveness, and environmental friendliness. By investing in a high-quality coated roofing machine and ensuring proper maintenance, roofing professionals can deliver superior-quality coated roofing materials that withstand the test of time.