Introduction

Bar straightening machines are an essential tool in the manufacturing industry, particularly in the production of bars and rods made of metal or other materials. These machines play a crucial role in ensuring the straightness and precision of bars, leading to improved quality and performance in various applications. In this article, we will explore the key aspects and functionalities of bar straightening machines, shedding light on their importance and the benefits they offer.

The Basics of Bar Straightening Machines

Bar straightening machines, also known as bar straighteners, are mechanical devices designed to straighten and align bars, rods, or other cylindrical workpieces. These machines are commonly used in industries such as construction, automotive, aerospace, and manufacturing, where straightness and dimensional accuracy are critical.

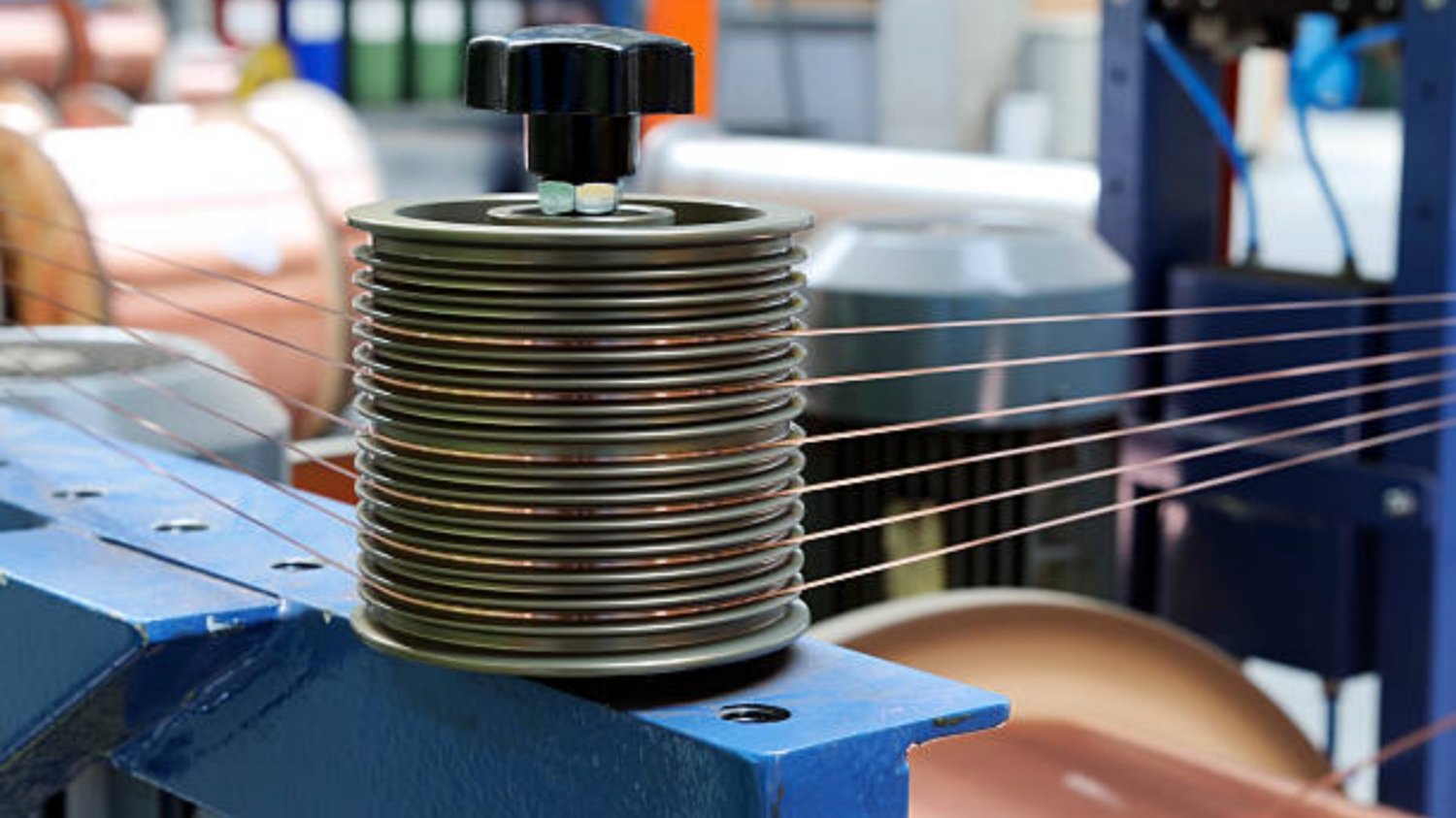

Bar straightening machines are equipped with a series of straightening rolls or rollers that exert pressure and force on the workpiece. These rolls are positioned in such a way that they gradually and incrementally straighten the bar as it passes through the machine. By applying controlled bending and straightening forces, these machines eliminate any existing bends, twists, or deformations in the bars, resulting in a perfectly straight end product.

The Working Principle of Bar Straightening Machines

Bar straightening machines operate on a simple yet effective principle. The workpiece, such as a bar or rod, is fed into the machine through a set of feeding rolls. As the workpiece passes through the machine, it encounters a series of straightening rolls that gradually correct its shape.

The straightening rolls are usually arranged in pairs, with one roll positioned above and the other below the workpiece. These rolls rotate in opposite directions, creating a bending moment that counteracts any existing bends or deformations in the bar. The combination of bending and counter-bending forces results in the straightening of the workpiece.

Types of Bar Straightening Machines

Bar straightening machines come in various types, each designed to cater to specific requirements and workpiece dimensions. The most common types of bar straightening machines include:

1. Two-Roll Bar Straightening Machines

Two-roll bar straightening machines are the simplest and most commonly used type. They consist of two rolls, one fixed and one adjustable, which allow for the straightening of bars with different diameters. These machines are suitable for straightening smaller bars and rods.

2. Four-Roll Bar Straightening Machines

Four-roll bar straightening machines are more advanced and versatile compared to two-roll machines. They feature two pairs of rolls, both of which can be adjusted to accommodate bars of various sizes. These machines offer enhanced straightening capabilities and are ideal for straightening larger and heavier bars.

3. Six-Roll Bar Straightening Machines

Six-roll bar straightening machines are the most advanced and sophisticated type. They consist of three pairs of rolls, each pair positioned at different angles. This design allows for superior straightening precision and the ability to handle bars with complex deformations or high straightness requirements.

Advantages of Bar Straightening Machines

Bar straightening machines offer numerous advantages, making them indispensable in the manufacturing industry. Some of the key benefits include:

1. Improved Straightness

The primary function of bar straightening machines is to ensure the straightness of bars and rods. By eliminating bends, twists, and deformations, these machines produce workpieces with superior straightness, meeting the strictest quality standards.

2. Enhanced Dimensional Accuracy

Bar straightening machines also contribute to improved dimensional accuracy. They can correct any deviations in diameter or roundness, resulting in workpieces with precise and consistent dimensions throughout their length.

3. Increased Productivity

Using bar straightening machines significantly increases productivity in manufacturing processes. Straightened bars require less manual handling and preparation, reducing labor costs and minimizing the risk of errors or defects.

4. Cost Savings

By producing straightened bars with high accuracy, bar straightening machines minimize material waste. Straighter bars also lead to better performance and longevity in various applications, reducing the need for frequent replacements or repairs.

5. Versatility and Flexibility

Bar straightening machines come in different types and configurations, offering versatility and flexibility to accommodate various workpiece dimensions and materials. This adaptability makes these machines suitable for a wide range of industries and applications.

Conclusion

Bar straightening machines are essential tools in the manufacturing industry, ensuring the straightness and dimensional accuracy of bars and rods. With their various types and functionalities, these machines play a crucial role in improving product quality, increasing productivity, and minimizing material waste. Investing in a bar straightening machine can bring significant benefits to businesses across different sectors, ultimately leading to enhanced efficiency and profitability.