The Basics of Slitting and Cutting

Slitting and cutting are two different methods of reducing the size of a material to a smaller, more usable size. While they may sound similar, they involve different processes, equipment, and goals. This article will provide an in-depth look at the differences between slitting and cutting, and how they are used in different industries and applications.

Slitting

Slitting is a process that involves cutting a material into multiple narrower strips. It is often used with materials that are too wide to be used in their original size, or for materials that need to be divided into smaller sections. Slitting machines use sharp, rotating blades to make precise cuts through materials such as metal, paper, plastic, and fabric. The resulting strips can be used for a wide variety of applications, including packaging, printing, and manufacturing.

Cutting

Cutting is a broader term that encompasses a variety of methods for separating a material into smaller pieces. Unlike slitting, cutting can involve cutting materials into shapes other than strips. Cutting methods can include sawing, shearing, punching, and drilling. Cutting machines may use laser beams, water jets, or high-speed blades to make clean and precise cuts through materials such as wood, metal, and plastics. The resulting pieces can be used for a wide variety of applications, including construction, automotive, and aerospace industries.

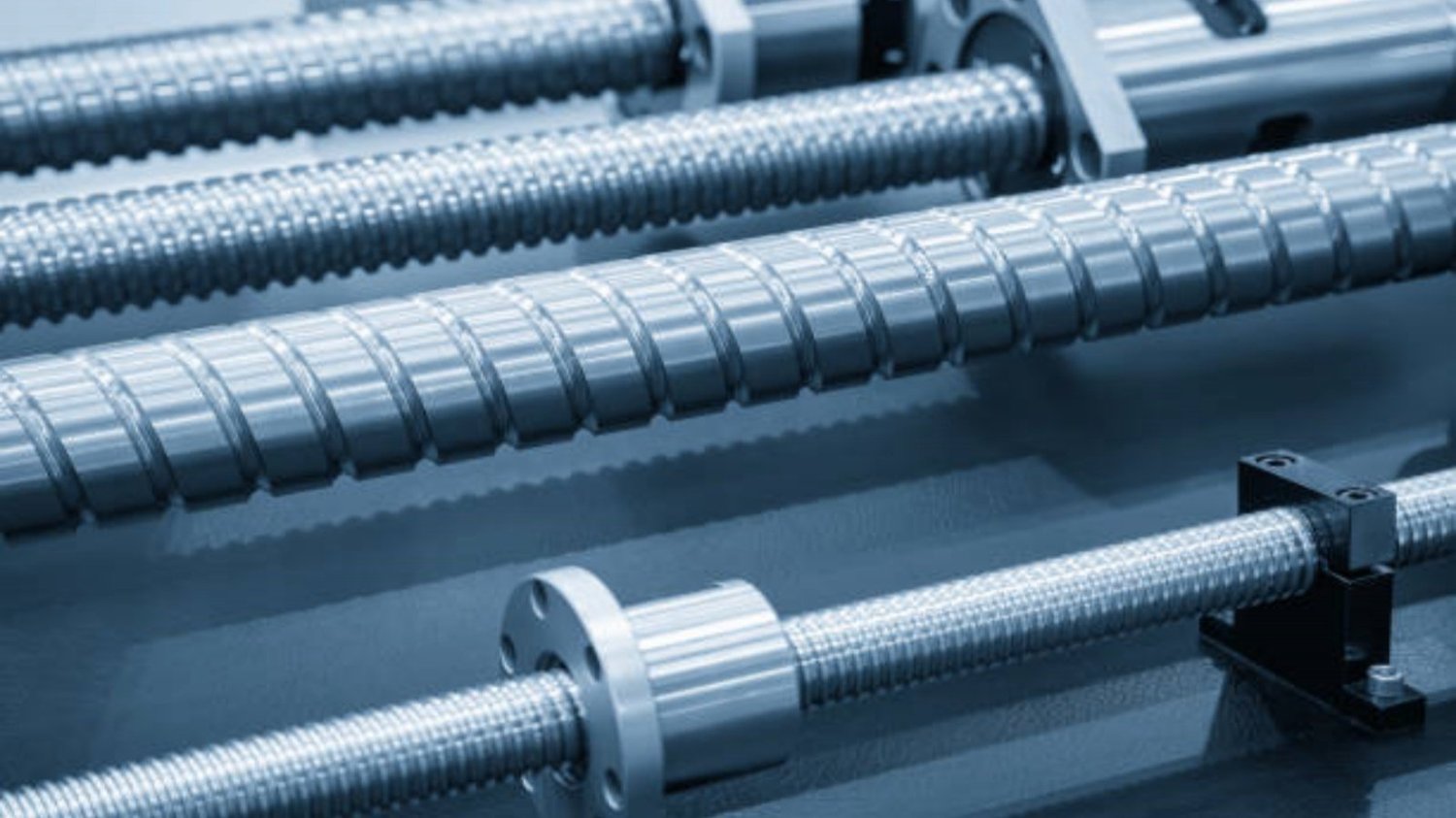

Differences in Equipment

Some of the most significant differences between slitting and cutting involve the equipment and machinery used. Slitting machines often use a set of rotating blades arranged in a circular pattern, while cutting machines may use saw blades, laser beams, or high-speed cutting blades. Slitting machines may require additional components, such as spacers, to ensure that materials are cleanly and precisely cut. Cutting machines may require more advanced technology, such as computer-controlled automation, to ensure accuracy and efficiency.

Differences in Materials

Another key difference between slitting and cutting involves the types of materials that are most commonly used. Slitting is often used with materials that are flexible or easily deformed, such as paper, plastic, and fabric. Cutting is more commonly used with rigid or tough materials such as metal, wood, and ceramics. Some materials may be cut using either method, depending on the required outcome.

Differences in Applications

Slitting and cutting are used in a wide variety of applications across many industries. However, slitting is often used in applications that require continuous production, such as large-scale manufacturing or printing processes. Cutting is often used in applications that require precision, such as machining parts for aerospace equipment or medical devices. Both methods can be used in applications such as packaging, construction, and automotive industries.

Differences in Precision

One of the biggest differences between slitting and cutting is the level of precision they offer. Slitting is often used when a high degree of precision is not required, or when small variations in size are acceptable. Cutting, on the other hand, can provide highly precise cuts with minimal deviation. This precision can be particularly important in scientific and medical applications, where even small errors can have serious consequences.

Differences in Cost

The cost of slitting and cutting can also vary significantly, depending on the materials, equipment, and methods used. Slitting may be less expensive than cutting, as it often requires less complex machinery and can be done more quickly. However, cutting can offer greater precision and may be more cost-effective in the long run, as it can reduce waste and improve efficiency.

Choosing the Right Method

Choosing between slitting and cutting depends on a variety of factors, including the material being used, the required precision, and the intended application. It is important to carefully consider these factors and select the method that best meets your needs. Consulting with experts in the industry can help ensure that you make the right decision.

Conclusion

Slitting and cutting are two distinct methods of reducing the size of a material to a more usable form. While they may sound similar, they involve different processes, equipment, and goals. Careful consideration of the material being used, the precision required, and the intended application is critical when choosing between the two methods. By understanding the differences between slitting and cutting, you can make informed decisions and achieve optimal results.