Customizable metal stud roll forming machine

Providing innovative machinery from IBR trapezoid to glazed tiles manufacturers.

Revolutionize roofing with innovative machinery.

Comprehensive support for enduring success.

Providing innovative machinery from IBR trapezoid to glazed tiles manufacturers.

Revolutionize roofing with innovative machinery.

Comprehensive support for enduring success.

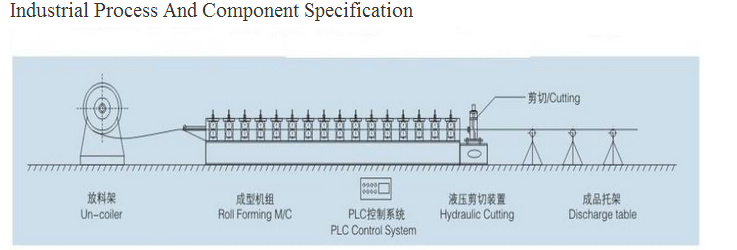

Introduction to Metal Stud Roll Forming Machine

A metal stud roll forming machine is a versatile piece of equipment that is specifically designed to produce metal studs used in construction projects. This machine utilizes a roll forming process to shape metal coils into precise and consistent studs. With its advanced technology and efficient operation, the metal stud roll forming machine offers numerous benefits in terms of speed, accuracy, and cost-effectiveness.

1. High Precision and Accuracy

The metal stud roll forming machine is engineered to deliver exceptional precision and accuracy in producing metal studs. Its automated system ensures consistent measurements and tight tolerances, resulting in perfectly formed studs every time. This level of precision is crucial for ensuring the structural integrity and stability of the finished construction projects.

2. Versatile and Customizable

One of the major advantages of a metal stud roll forming machine is its versatility and ability to produce studs of various sizes and shapes. The machine can be easily adjusted and customized to meet specific project requirements. Whether you need studs with different thicknesses, lengths, or profiles, this machine can efficiently accommodate those needs.

3. Efficient Production Speed

By utilizing advanced roll forming technology, the metal stud roll forming machine enables fast and efficient production of metal studs. It can process metal coils at high speeds, significantly reducing production time compared to traditional methods. This increased productivity allows for quicker project completion and helps meet tight deadlines.

4. Cost-Effective Solution

The use of a metal stud roll forming machine offers cost savings in various ways. Firstly, it eliminates the need for manual labor-intensive processes, reducing labor costs. Secondly, it minimizes material waste by optimizing the use of metal coils, resulting in lower material expenses. Lastly, the machine's long lifespan and low maintenance requirements contribute to overall cost-effectiveness.

5. Superior Quality and Durability

Metal studs produced by a roll forming machine exhibit superior quality and durability compared to those produced through other methods. The machine ensures consistent material thickness, smooth edges, and accurate dimensions, resulting in studs that meet the highest quality standards. These high-quality studs provide long-lasting structural support in various construction applications.

6. Easy Operation and Control

The metal stud roll forming machine is designed for user-friendly operation and control. Its intuitive interface and automated functions make it easy for operators to set parameters, monitor production, and make adjustments as needed. Minimal training is required, allowing operators to quickly become proficient in operating the machine.

7. Energy Efficiency

With a focus on sustainability, the metal stud roll forming machine is designed to be energy-efficient. It utilizes advanced technologies and optimized processes to minimize energy consumption without compromising production efficiency. This energy-saving feature contributes to reducing environmental impact and operating costs.

8. Robust Construction and Safety Features

Metal stud roll forming machines are built with robust construction to ensure durability and long-term reliability. They are equipped with safety features such as emergency stop buttons, safety guards, and sensors to protect operators from potential hazards. This commitment to safety ensures a secure working environment for operators.

9. Seamless Integration with Production Lines

The metal stud roll forming machine can be seamlessly integrated into existing production lines or used as a standalone unit. Its compact design and flexible configuration options allow for easy installation and integration with other equipment. This integration capability enhances overall production efficiency and workflow.

10. Wide Range of Applications

Metal studs produced by roll forming machines have a wide range of applications in the construction industry. They are commonly used in framing walls, partitions, ceilings, and other structural elements. The versatility and strength of these studs make them suitable for both residential and commercial construction projects.

Certificates

Our company in the "mechanical" industry takes great pride in the numerous industry certificates we have obtained over the years, which serve as a testament to our commitment to excellence and expertise. These certifications not only validate our dedication to quality, but also highlight our ability to meet and exceed industry standards. With our extensive knowledge and experience, we continuously strive to deliver cutting-edge products that are highly competitive in the market. By leveraging our industry certificates, we can confidently assure our customers that our offerings are backed by rigorous testing, superior craftsmanship, and the highest level of performance. Choosing our products means choosing reliability, durability, and innovation, making us the preferred choice in the industry.