Versatile slitting line

Providing innovative machinery from IBR trapezoid to glazed tiles manufacturers.

Revolutionize roofing with innovative machinery.

Comprehensive support for enduring success.

Providing innovative machinery from IBR trapezoid to glazed tiles manufacturers.

Revolutionize roofing with innovative machinery.

Comprehensive support for enduring success.

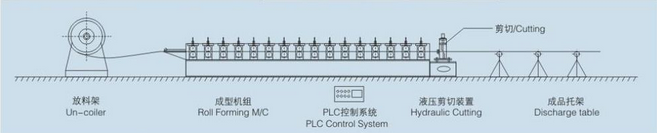

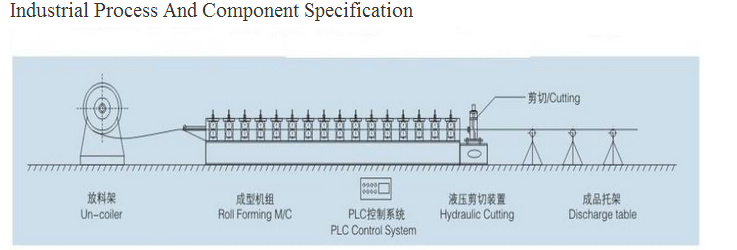

Slitting Line: Efficient and Versatile Machine for Precision Slitting

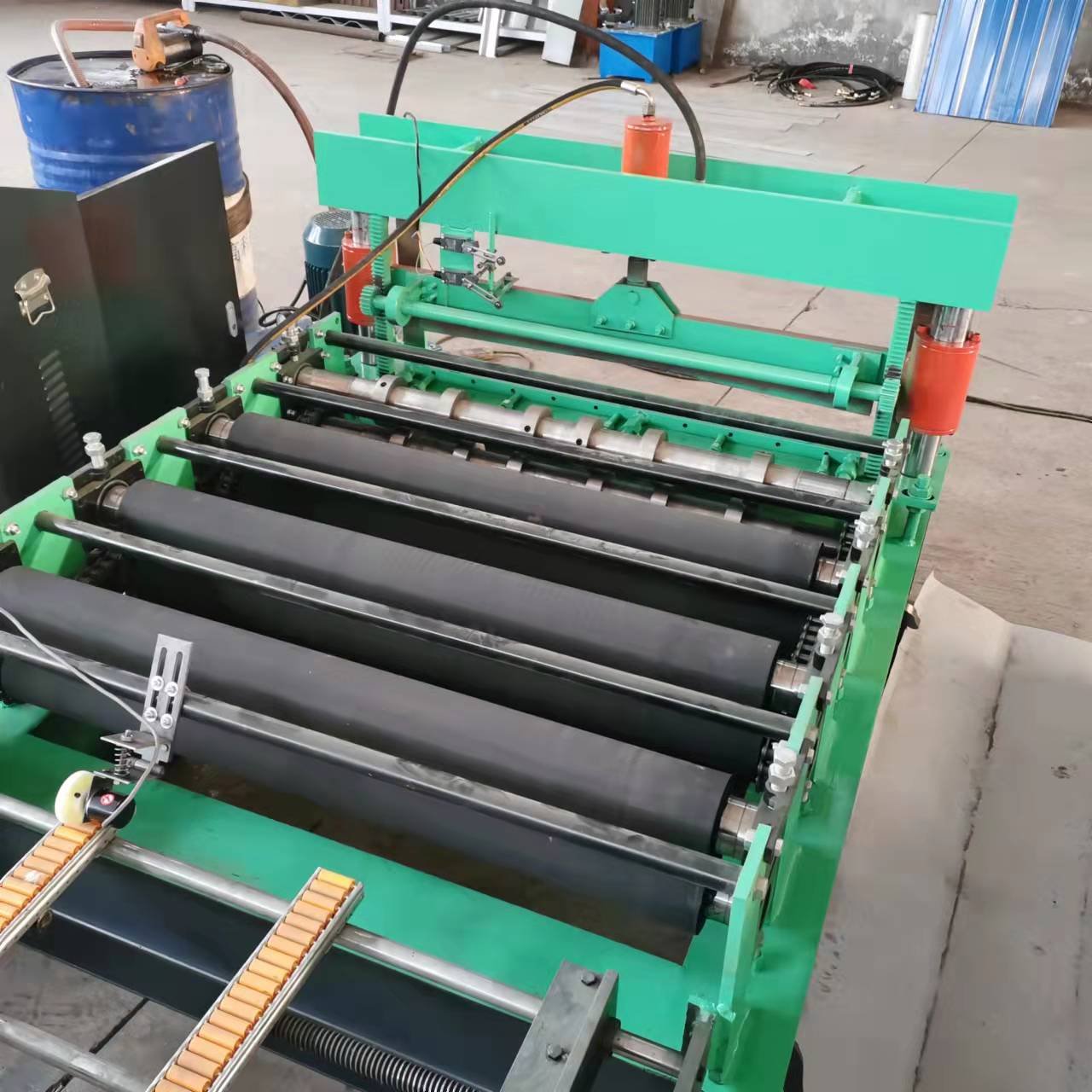

Slitting line is a cutting-edge machine designed to provide precise and efficient slitting of various materials. With its advanced features and robust construction, this versatile equipment is an essential tool for industries involved in metal processing, steel coil slitting, and similar applications. Whether you are a large-scale manufacturer or a small business owner, this slitting line offers unparalleled performance and reliability, making it an excellent investment for your operations.

High-precision Slitting for Optimal Material Utilization

The slitting line is equipped with state-of-the-art slitting technology, allowing you to achieve exceptional precision in material slitting. Its razor-sharp blades and adjustable cutting parameters ensure clean and accurate cuts, minimizing material waste and maximizing material utilization. By optimizing the slitting process, you can significantly reduce production costs and increase overall efficiency.

Flexible Coil Handling and Processing

With its versatile design, the slitting line can handle a wide range of coil sizes and materials. Whether you are working with steel, aluminum, copper, or other metals, this machine can effortlessly process coils of various thicknesses and widths. Its adjustable mandrel expansion system ensures secure coil loading and precise alignment, enabling smooth and efficient processing.

Efficient Strip Recoiling for Easy Handling

The slitting line features a high-speed recoiling system that neatly winds the slit strips into tight and uniform coils. This efficient recoiling process not only facilitates easy handling and transportation but also minimizes the risk of damage to the slit strips. The machine's automatic strip tension control ensures consistent coil tightness, further enhancing the reliability and quality of the finished coils.

Advanced Control System for Enhanced Productivity

Equipped with an advanced control system, the slitting line offers intuitive operation and precise control over the slitting process. The user-friendly interface allows operators to easily set and adjust cutting parameters, monitor production status, and diagnose any potential issues. With real-time feedback and automatic error detection, this control system ensures optimal productivity and minimizes downtime.

Safety Features for Operator Protection

Prioritizing operator safety, the slitting line incorporates various safety features to prevent accidents and injuries. The machine is equipped with emergency stop buttons, safety interlocks, and protective covers to safeguard operators from potential hazards. Additionally, the control system includes comprehensive safety protocols and alarms to alert operators of any abnormal conditions, ensuring a secure working environment.

Robust Construction for Long-lasting Performance

The slitting line is built to withstand demanding industrial environments and deliver reliable performance over extended periods. Its heavy-duty frame and high-quality components ensure durability and minimal maintenance requirements. The machine's robust construction guarantees long-lasting performance, allowing you to focus on your production without worrying about frequent breakdowns or downtime.

Quick Setup and Changeover for Improved Efficiency

Designed for efficiency and convenience, the slitting line offers quick setup and changeover capabilities. The machine's tool-less blade positioning system enables easy blade changes, reducing downtime during coil material transitions. Furthermore, the intuitive setup procedures and automated adjustments streamline the overall setup process, enabling faster production and increased productivity.

Energy-efficient Operation for Cost Savings

The slitting line incorporates energy-saving features to minimize power consumption and reduce operating costs. The machine's advanced motor control system optimizes energy usage by adjusting speed and power output according to the specific slitting requirements. This energy-efficient operation not only contributes to cost savings but also reduces the environmental impact of your operations.

Compliance with Industry Standards and Regulations

Our slitting line complies with all relevant industry standards and regulations, ensuring the highest quality and safety standards. We prioritize adherence to international guidelines to guarantee that our machine meets or exceeds the expectations of our customers. By choosing our slitting line, you can have confidence in its performance, reliability, and compliance with industry best practices.

Certificates

Our company in the "mechanical" industry takes great pride in the numerous industry certificates we have obtained over the years, which serve as a testament to our commitment to excellence and expertise. These certifications not only validate our dedication to quality, but also highlight our ability to meet and exceed industry standards. With our extensive knowledge and experience, we continuously strive to deliver cutting-edge products that are highly competitive in the market. By leveraging our industry certificates, we can confidently assure our customers that our offerings are backed by rigorous testing, superior craftsmanship, and the highest level of performance. Choosing our products means choosing reliability, durability, and innovation, making us the preferred choice in the industry.