Accurate cold formed steel machine

Providing innovative machinery from IBR trapezoid to glazed tiles manufacturers.

Revolutionize roofing with innovative machinery.

Comprehensive support for enduring success.

Providing innovative machinery from IBR trapezoid to glazed tiles manufacturers.

Revolutionize roofing with innovative machinery.

Comprehensive support for enduring success.

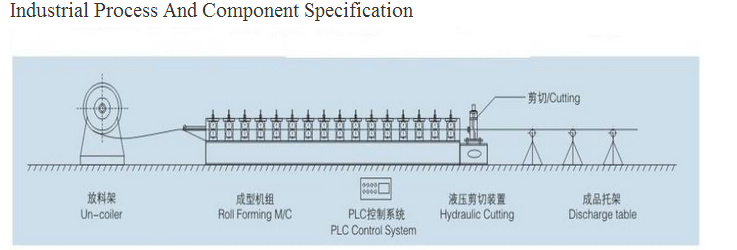

Introduction to Cold Formed Steel Machine

A cold formed steel machine is a cutting-edge piece of equipment used in the manufacturing industry to produce high-quality cold formed steel products. This machine utilizes advanced technology and precision engineering to transform raw materials into finished products, meeting the demands of various industries. With its efficiency and versatility, the cold formed steel machine has revolutionized the production process, enabling faster and more cost-effective manufacturing.

1. Superior Precision and Accuracy

One of the key features of the cold formed steel machine is its ability to deliver exceptional precision and accuracy. Through advanced control systems and precise tooling, this machine ensures that each steel component is formed with the utmost accuracy, meeting the strictest quality standards. This level of precision guarantees consistent product dimensions and shapes, making it ideal for applications that require tight tolerances.

2. Versatility in Product Design

The cold formed steel machine offers unparalleled versatility in product design. With adjustable tooling and customizable settings, this machine can produce a wide range of steel components with different shapes, sizes, and configurations. Whether it's C-sections, Z-sections, or custom profiles, the cold formed steel machine can effortlessly accommodate various design requirements, providing endless possibilities for product innovation.

3. Efficient Production Process

With its advanced automation capabilities, the cold formed steel machine streamlines the production process, significantly improving efficiency and productivity. This machine operates at high speeds, allowing for rapid production of steel components without compromising quality. Its automated features also minimize human error, reducing the need for manual interventions and increasing overall production output.

4. Cost-Effectiveness and Material Savings

The cold formed steel machine offers substantial cost savings and material efficiency. By utilizing cold forming technology, this machine optimizes the use of raw materials, minimizing waste and reducing production costs. Additionally, the efficient production process and high-speed capabilities of the machine contribute to cost-effectiveness by reducing labor expenses and increasing overall productivity.

5. Durability and Longevity

Constructed from high-quality materials and designed for heavy-duty use, the cold formed steel machine is built to last. Its robust structure and reliable components ensure durability and longevity, withstanding the rigors of continuous operation. This machine's longevity translates to long-term cost savings, as it requires minimal maintenance and has a low risk of breakdowns or downtime.

6. Integration with Existing Production Lines

The cold formed steel machine is designed to seamlessly integrate into existing production lines, making it an ideal choice for manufacturers looking to upgrade their operations. Whether it's a standalone machine or part of a larger manufacturing system, this machine can be easily integrated into the workflow, enhancing overall efficiency and productivity without disrupting the existing production processes.

7. Energy Efficiency

As energy efficiency becomes a crucial consideration in modern manufacturing, the cold formed steel machine stands out as an environmentally friendly option. This machine is designed to minimize energy consumption through advanced engineering and optimized operational processes. By reducing energy waste, manufacturers can not only save on utility costs but also contribute to sustainability efforts.

8. Compliance with Industry Standards

The cold formed steel machine adheres to the highest industry standards, ensuring that the manufactured steel components meet all relevant specifications and regulations. This compliance is essential for industries such as construction, automotive, and aerospace, where product quality and safety are paramount. By investing in a cold formed steel machine, manufacturers can confidently deliver products that meet or exceed industry standards.

9. Technical Support and Training

When purchasing a cold formed steel machine, manufacturers can expect comprehensive technical support and training from the supplier. Experienced technicians provide installation assistance, machine calibration, and troubleshooting services to ensure smooth operation. Additionally, training programs are available to equip operators with the necessary skills and knowledge to maximize the machine's capabilities, ensuring optimal performance and efficiency.

10. Continuous Innovation and Upgrades

The cold formed steel machine industry is continuously evolving, with manufacturers investing in research and development to enhance machine capabilities and introduce new features. By choosing a reputable supplier, manufacturers can benefit from regular upgrades and access to the latest advancements in cold forming technology. This ensures that their cold formed steel machine remains at the forefront of innovation, enabling them to stay competitive in the ever-changing manufacturing landscape.

Certificates

Our company in the "mechanical" industry takes great pride in the numerous industry certificates we have obtained over the years, which serve as a testament to our commitment to excellence and expertise. These certifications not only validate our dedication to quality, but also highlight our ability to meet and exceed industry standards. With our extensive knowledge and experience, we continuously strive to deliver cutting-edge products that are highly competitive in the market. By leveraging our industry certificates, we can confidently assure our customers that our offerings are backed by rigorous testing, superior craftsmanship, and the highest level of performance. Choosing our products means choosing reliability, durability, and innovation, making us the preferred choice in the industry.