Double layer roof tile roll forming machine

Providing innovative machinery from IBR trapezoid to glazed tiles manufacturers.

Revolutionize roofing with innovative machinery.

Comprehensive support for enduring success.

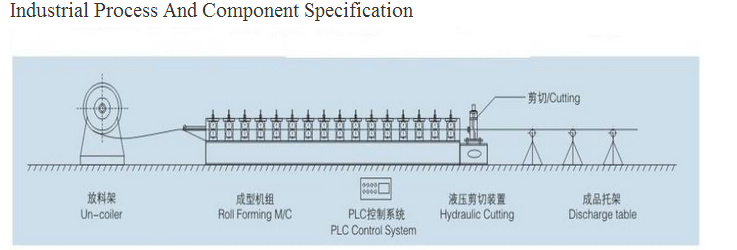

Product Description

Introducing our Double Layer Roof Tile Roll Forming Machine, the ultimate solution for your roofing needs! This cutting-edge machinery is designed to provide exceptional efficiency and precision in manufacturing roof tiles. With its advanced features and functions, it enables seamless production of high-quality roof tiles, ensuring durability and excellence. Its dual-layer design allows for increased productivity, as it can produce two different types of tiles simultaneously. Our machine boasts a wide range of applications, making it suitable for various roofing projects. Its user-friendly interface ensures ease of operation, while its robust construction guarantees long-lasting performance. Invest in our Double Layer Roof Tile Roll Forming Machine and experience unmatched productivity and profitability in the manufacturing industry!

Product Features

- Double layer roof tile roll forming machine

- Product Keywords: roof tile roll forming machine

- Core can be extracted without expansion

- Efficient and precise roll forming process

- High-quality double layer roof tile production

- Durable and long-lasting machine construction

Application of roof tile roll forming machine

- The double layer roof tile roll forming machine is designed to efficiently produce high-quality roof tiles.

- It is suitable for manufacturing various types of roof tiles, including double layer tiles.

- This machine is perfect for industries involved in roofing and construction, providing a cost-effective solution for tile production.

- It ensures a smooth and precise roll forming process, resulting in accurate and consistent roof tiles.

- The machine's double layer design allows for increased productivity by producing two layers of tiles simultaneously.

- With its advanced technology and sturdy construction, it guarantees durability and longevity.

Hydraulic cutting device

This device for decking products cutting.Whole unit structure with steel plate welded,stable and strengthed.

With double guide pillar,ensure cutting process stable and smoothly.

Double cylinders,use steel oil pipe instead of rubber oil pipe,durable and beautiful.High strength sealing ring joint to avoid oil leakage.

Cutting blade base will be T type with milling machine processing for improving flatness,thereby extending the service life of the cutting tool.

Cutting blade material will be Cr 12Mov.

Quenched 58-60 to ensure hardness.

Electrical control system

Control Unit mainly for Delta,including 7inch HMI and PLC.

Low voltage Components:Delixi or schneider.

Frequency Changer/Inverter:ZONCN/Delta

Encoder Brand:Omron

All electrical brands are well-known domestic and foreign brands with 3C/CE/UL standard

Roll forming machine

Frame main structure:H-beam.

Sidewall/Wallboard structure:14/16mm.

Shaft material:45# steel,solid shaft.Dia 70-75mm.

Roller shaft processing:Rough turning followed by precision turning,cylindrical grinding machine processing to ensure assembly accuracy,keyway processing to closely coordinate with the roller wheel for rotation.

Roller mold:45# steel .CNC lathing.

Transmission:Sprocket and chain

Driving Method:Reducer

Drive system

We have close cooperation with well-known motor brands both domestically and internationally,such as Shanghai,Siemens,ABB,etc.Additionally,we recommend servo drive motors,for increasing production speed by more than 60%.

Transmission by gear and chain for stable working.Gear with quenched processing for long period production,1 inch chain for more stronger transmission,longer life,lower maintance cost.

The chain part is fully covered with protective cover for human safety.According to different design needs,gear box drive can be selected to make the machine run smoothly.

Feeding platform

Whole unit structure with steel plate welded,stable and strengthed.

There are material blocking square iron on the left and right sides to prevent the steel plate from deviating.Both sides are equipped with handles to adjust feeding width.

Feeding platform with position indicator used for record the position of the last feeding production,so that the production process can be traced.

Optional: We can add hydraulic front shear after the feeding platform and before forming the rollers,with the main purpose of calculating the overall production length and reducing waste generation.

Certificates

Our company in the "mechanical" industry takes great pride in the numerous industry certificates we have obtained over the years, which serve as a testament to our commitment to excellence and expertise. These certifications not only validate our dedication to quality, but also highlight our ability to meet and exceed industry standards. With our extensive knowledge and experience, we continuously strive to deliver cutting-edge products that are highly competitive in the market. By leveraging our industry certificates, we can confidently assure our customers that our offerings are backed by rigorous testing, superior craftsmanship, and the highest level of performance. Choosing our products means choosing reliability, durability, and innovation, making us the preferred choice in the industry.