Roll former machine for sale

Providing innovative machinery from IBR trapezoid to glazed tiles manufacturers.

Revolutionize roofing with innovative machinery.

Comprehensive support for enduring success.

Providing innovative machinery from IBR trapezoid to glazed tiles manufacturers.

Revolutionize roofing with innovative machinery.

Comprehensive support for enduring success.

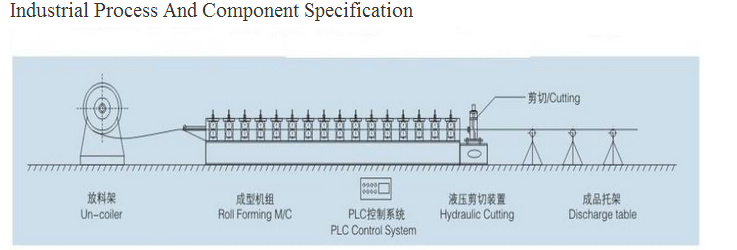

Understanding the Roll Former Machine and Its Functions

A roll former machine is a vital piece of equipment used in the metal fabrication industry. It is designed to shape metal sheets into specific profiles and shapes, such as roofing panels, gutters, and wall cladding. This machine utilizes a series of rolls to gradually bend and form the metal sheet into the desired shape. The rolls are strategically positioned along a line, and as the metal sheet passes through, each roll bends and molds the sheet until the desired profile is achieved. Roll former machines are highly efficient and can produce large quantities of consistent and precise metal profiles, making them invaluable in various construction and manufacturing applications.

Benefits of Investing in a Roll Former Machine

Investing in a roll former machine offers numerous benefits for metal fabricators and manufacturers. Firstly, these machines significantly increase productivity. With their ability to produce large quantities of precise metal profiles, roll former machines can streamline production processes and reduce labor costs. Additionally, roll formers offer versatility, as they can be adjusted to create different profiles by simply changing the tooling. This flexibility allows manufacturers to adapt to changing market demands and expand their product offerings. Moreover, using a roll former machine ensures consistent quality in the produced profiles, eliminating variations that may occur with manual fabrication methods. This consistency not only enhances the product's durability but also improves customer satisfaction. Overall, investing in a roll former machine can lead to increased efficiency, cost savings, and improved product quality.

Factors to Consider When Purchasing a Roll Former Machine

When considering the purchase of a roll former machine, several factors should be taken into account. Firstly, the machine's capacity and capabilities should align with the specific requirements of the intended applications. It is crucial to assess the maximum sheet thickness and width that the machine can handle, as well as the range of profiles it can produce. Additionally, the machine's durability and reliability should be evaluated to ensure it can withstand continuous operation and deliver consistent results. Other important considerations include the availability of technical support and spare parts, as well as the machine's overall cost and return on investment. By thoroughly assessing these factors, metal fabricators can make an informed decision and select a roll former machine that best suits their production needs.

Finding a Roll Former Machine for Sale

Finding a roll former machine for sale can be done through various channels. One option is to directly contact manufacturers and suppliers specializing in metal fabrication equipment. They can provide information about available models, specifications, and pricing. Additionally, online marketplaces and industrial auctions can be valuable sources for purchasing both new and used roll former machines. These platforms offer a wide range of options and allow buyers to compare prices and specifications. It is essential to thoroughly research the reputation and credibility of the seller before making a purchase to ensure a reliable transaction. By exploring these avenues, metal fabricators can find a roll former machine that meets their specific requirements while staying within their budget.

Certificates

Our company in the "mechanical" industry takes great pride in the numerous industry certificates we have obtained over the years, which serve as a testament to our commitment to excellence and expertise. These certifications not only validate our dedication to quality, but also highlight our ability to meet and exceed industry standards. With our extensive knowledge and experience, we continuously strive to deliver cutting-edge products that are highly competitive in the market. By leveraging our industry certificates, we can confidently assure our customers that our offerings are backed by rigorous testing, superior craftsmanship, and the highest level of performance. Choosing our products means choosing reliability, durability, and innovation, making us the preferred choice in the industry.